The choice of fire-resistant plastics depends on their intended usage. Today’s article covers everything about flame-resistant plastics.

Are you curious to know:

- What are fire-resistant plastics?

- Their types;

- And how do these mini-firefighters benefit you in different areas of life?

Keep reading this well-researched article that helps you make the most informed decision about choosing the most befitting fire-resistant plastic.

What are Fire Resistant Plastics?

Fire-resistant plastics, also called flame-retardant plastics or self-extinguishing plastics, are engineered plastics that offer better fire safety by slowing the progression of flames. Special chemicals add prolonged fire resistance to these plastics, following fire safety standards like UL 94. This extra fire protection offered by these special plastics saves people and buildings in case of fire.

Although impressive, flame-resistant plastic materials (often self-extinguishing) aren’t completely fireproof. Instead, their unique chemical properties make them fight fire better. These chemicals interfere with the chain reaction between fuel, fire, and oxygen in different ways and improve fire retardancy by:

- Delaying ignition

- Promoting self-extinguishing (for example, coming from phosphorous-based flame retardants)

- Slowing the burning process

To add high-temperature resistance power to the plastics, different chemicals are used:

- Phosphate: These chemical compounds release non-flammable gasses in the form of bubbles to reduce the oxygen supply for the burning process.

- Halogènes: Reactive flame retardants like bromine and chlorine form a protective char layer when heated. This layer acts like a shield to keep oxygen away from reaching the burning plastic.

- Nitrogen Compounds (Melamine): These chemicals release non-flammable gasses or water vapors to slow down fire expansion.

- Metals (Antimony): Some fire-resistant plastics have metal particles mixed in, which absorb heat and keep the plastic cooler. So, the ignition becomes challenging.

- Silicone-Based Plastics: They block oxygen or release inert gasses to keep flames away. However, being costly, they are used only in tough conditions, where little quantity of high-quality flame-resistant material is needed to fight high temperatures. Joints et joints are a common example of this.

These flame retardants improve the fire safety of plastics and even lead to self-extinguishing once the flame source is removed.

Envoyez votre demande maintenant!

La qualité rencontre l'abordabilité. Renseignez-vous maintenant pour des produits de haute qualité à faibles volumes.

Types of Fire-Resistant Plastics

Considering their chemical formulation and structure, flame-resistant materials can be categorized as:

- Inherently fire-resistant plastics

- Enhanced plastics.

Their efficacy, cost-effectiveness, and application vary according to the type. Below is a breakdown of each type:

Inherently Fire Resistance Plastics

Although man-made, these plastics boast a chemical structure that makes them difficult to ignite and burn. Some of these plastics include:

- Polyphenylene sulfone (PPS): This plastic features excellent flame retardancy at high temperatures–It doesn’t melt easily. It’s commonly used in electrical components and demanding aerospace applications.

- Polytétrafluoroéthylène (PTFE): With a natural chemical formulation of C2F4, it’s also known as Teflon. It doesn’t burn quickly and even helps extinguish flames. PTFE is used to make nonstick cookware and electrical wiring insulation.

- Polyimide (PI): This high-performance plastic offers extreme fire resistance and exceptional thermal stability. Therefore, it’s widely used in challenging conditions like aircraft engines and spacecraft.

Scientists are developing new fire-resistant plastics for various applications in different industries. So, their future list of these plastics can be exhaustive.

Plastics with Fire Retardant Additives

You can find many chemically enhanced fire-resistant plastics with unique flame-retardant properties. Here are two common types:

1. Intumescent Plastics

For fire resistance, these flame-retardant plastics rely on chemicals like acide phosphorique (H3PO4) et pentaérythritol (C(CH2OH)4). On heat exposure, these chemicals swell up to form a thick char layer. This layer blankets the plastic underneath and slows the fire spread. Common examples of intumescent plastics are:

- Polyphénylène Sulfure (PPS)

- Polyamide-imide (PAI)

- Éthylène-acétate de vinyle (EVA) (when formulated with intumescent flame retardant additives)

- Unsaturated Polyester Resins (UP resins) (when formulated with intumescent additives)

2. Halogenated Plastics

These plastics use mixed-in additives or reactive flame retardants. Among these, halogen elements like bromine (for brominated flame retardants) or chlorine (Cl) are commonly used to enhance fire resistance. During a fire, they release halogenated hydrocarbons to interfere with the chemical reactions in the fire. Consequently, it becomes harder for the fire to continue burning.

Halogenated plastics like polycarbonate (PC) and ABS are often used in electronic components or airplane parts. For this purpose, they’re treated with halogenated flame retardants to enhance their fire resistance.

Both halogenated and halogen-free flame retardants are chosen according to the desired safety, robustness, and cost-effectiveness.

The table below summarizes some of the most common types of fire-resistant plastics, their resistance level, and applications:

| Type de plastique | Inherently Fire Resistant | Fire Retardant Additives | Ease of Extrusion | Applications |

|---|---|---|---|---|

| Polyphénylène Sulfure (PPS) | Oui | Non | Modérés | Electrical components, high-temperature gears, pump components |

| PEEK (Polyétheréthercétone) | Oui | parfois | Modérés | Aerospace components, medical implants, chemical processing equipment |

| Polytétrafluoroéthylène (PTFE) | Oui | Non | Difficile | Chemical processing equipment, electrical insulation, non-stick coatings |

| Polyimide (PI) | Oui | parfois | Difficile | High-temperature electronics, flexible circuits, spacecraft components |

| Flame-Retardant Polycarbonate (FR-PC) | Non | Oui | Modérés | Electronic enclosures, safety helmets, bullet-resistant glass |

| Flame-Retardant ABS (FR-ABS) | Non | Oui | Entretien | Electronics casings, automotive parts, household appliances |

| Flame-Retardant Polyamide (FR-PA) | Non | Oui | Modérés | Gears, machine parts, electrical connectors |

| Polyphosphazene (PPZ) | Oui | Non | Difficile | Flame retardant textiles, aerospace components |

| Silicones | Oui | parfois | Modérés | Gaskets, seals, high-temperature insulation, medical devices |

| Ferrites | Oui | Non | Non applicable | Fireproof linings, high-temperature crucibles |

| Charring Thermoplastics | Non | Specific Additives | Variable | Cable insulation, building materials |

| Revêtements intumescents | Non | Additifs spéciaux | Non applicable | Steel structures, electrical components |

| Ablative Plastics | Non | Additives for Ablation | Variable | Rocket nozzles, heat shields |

Envoyez votre demande maintenant!

La qualité rencontre l'abordabilité. Renseignez-vous maintenant pour des produits de haute qualité à faibles volumes.

Benefits of Fire-Resistant Plastics

The incredible power of fire-resistant plastics, which makes fire-resistant plastics so beneficial:

1. Slower Burning

Fire-resistant plastics don’t catch fire easily, unlike regular plastics. Or if they catch fire, they burn much more slowly, giving people more time to escape a fire. This is because special chemicals or metals are added to these plastics. These chemicals block oxygen and release water vapors or non-flammable gasses that push the fire away from the plastic. And, if they have added metals, they absorb heat to reduce the fire spread rate.

2. Self-Extinguishing

Many fire-resistant plastics can put themselves out. Once the flame source is removed, they stop burning on their own. Result? A small fire doesn’t turn into a big one.

3. Réduction de la fumée

Regular plastics create potentially dangerous smoke while burning–Thick and black. This smoke limits vision and breathing during a fire. Resultantly, a quick escape becomes almost impossible. In contrast, fire-resistant plastics produce much less smoke, or sometimes none at all. This translates to remaining clear during a fire–people can get out of the buildings, and firefighters can see their way around more easily.

4. Protects Property

Fire can cause extensive damage to buildings, furniture, and other belongings. The use of fire-resistant plastics in building materials and other applications helps in preventing this damage. They burn gradually–the spread of flames is also delayed. So the firefighters have more time to put out the fire and save valuable property.

For example, fire-resistant plastics might be used in electrical components or appliance housings. If these parts catch fire, the fire-resistant plastic can help stop the flames from reaching other parts of the building.

5. Increased Safety of Crowded Buildings

With characteristics like slower burning, self-extinguishing, reduced smoke, and property protection, fire-resistant plastics make buildings and products safer overall. Thus, their use is crucial in places with many people, like schools, hospitals, airplanes, and shopping malls. Using fire-resistant plastics in these areas ensures reduced risk of injuries and deaths in case of a fire.

Hence, fire-resistant plastics play a key role in fire safety. By reducing fire spreading, smoke production, and extinguishing themselves, they allow people to escape a fire. At the same time, they help firefighters with better control to fight flames.

Applications of Fire-Resistant Plastics

Flame-resistant plastics are not fully fireproof but give you valuable extra time to react in a fire emergency. This is why their usage is widespread. Here are some popular applications of fire-resistant plastics that help keep you safe:

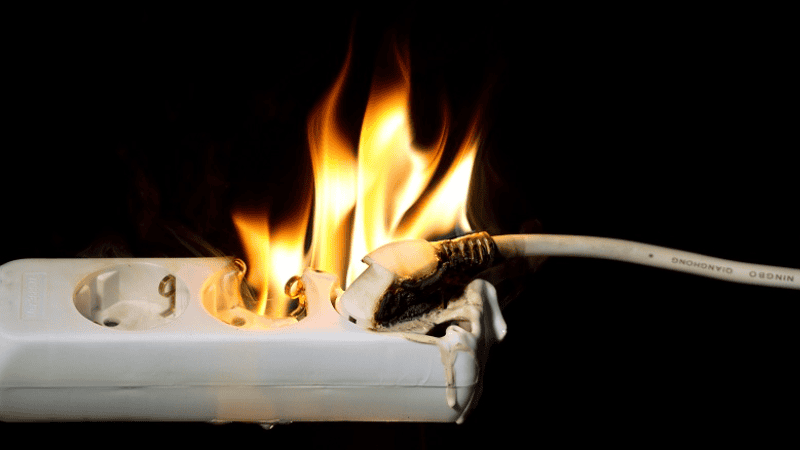

1. Sécurité électrique

Most electrical components like plugs, outlets, and wire casings are made with fire-resistant plastics. These plastics ensure that electrical sparks or malfunctions don’t lead to fires.

2. Appliance Housings

Many daily life appliances, like toasters, microwaves, and even computers, have plastic parts but are fire-resistant. This is the reason many times, you wonder why they don’t melt or catch fire even when heat or flames arise within the appliance.

3. Matériaux de construction

Building materials like wall panels, cable trays, pipes, and even doors use fire-resistant plastics. Therefore, the spread is slow in case of fire, and people have more time to get out of the building.

4. Furniture Safety

Most furniture in public places like hospitals, schools, universities, and terminals might have fire-resistant components. This helps keep people safe by slowing the spread of the fire and giving them more time to evacuate.

5. Aircraft Parts

Airplanes use fire-resistant plastics in various parts, from cabin panels to wire insulation, to improve passenger safety during emergencies.

6. Équipement de protection

Firefighters’ shields, helmets, and suits are made of fire-resistant plastics. These life-saving material protections keep them safe from excessive heat and flames when they battle fires.

7. Safer Transportation

Cars and other automobiles heavily depend on fire-resistant plastics when it comes to safety. Their interior components, like dashboards and seat belts, use fire-resistant plastics. This proactive approach prevents flames from quickly engulfing the vehicle’s interior.

8. Matériel médical

Ces dispositifs médicaux utilize fire-resistant plastics like ABS and polycarbonate because of their fire-retardant properties and ability to withstand high temperatures. This is because they ensure safety and reliability in medical settings. Some of these examples include MRI casings, plastic syringes, prosthetics, IV connectors used in renal dialysis, and cardiac surgery components.

9. Sécurité alimentaire

Specific food processing equipment and even cookware use fire-resistant plastics. Why? Fire retardants help minimize the risk of fires during food preparation, which may hurt the food makers or the food itself. For instance, machine guards are made from polycarbonate for food processing equipment. Conveyor belting materials are coated with PTFE or silicone for food processing applications. Likewise, cutting boards are made from HDPE for food preparation areas. The application of the fire retardant plastic in food preparation is exhaustive.

10. Everyday Items

Fire-resistant plastics have more uses than you might think! They’re not just for industrial applications. Even everyday items like tool handles, safety glasses, and some phone cases benefit from this fire-resistant technology.

Hence, the smart use of fire-resistant plastics in various applications creates safer environments for you. Therefore, they’ve become vital to lessen the fire-related damage to life and resources.

Envoyez votre demande maintenant!

La qualité rencontre l'abordabilité. Renseignez-vous maintenant pour des produits de haute qualité à faibles volumes.

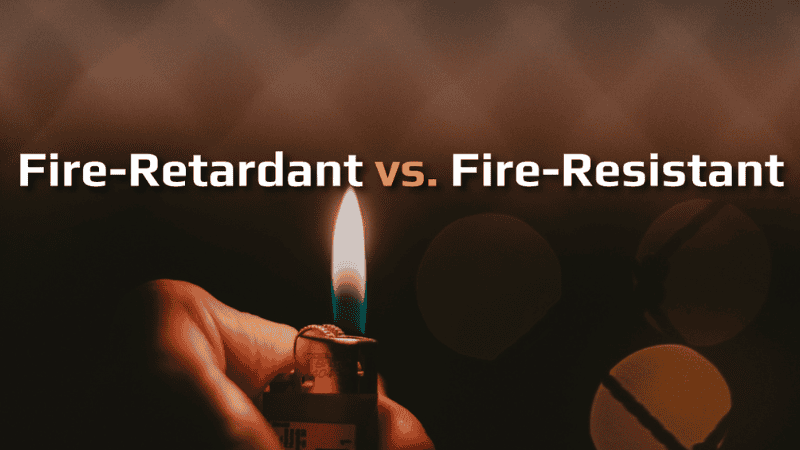

Fire Retardant vs. Fire Resistant Plastics

Two terms used for flame-fighting plastics, fire-resistant and fire-retardant plastics, cause enough confusion. Both types of plastics may sound similar, yet they’re different. Their functionality greatly determines their purposeful use.

The primary difference between fire-resistant and fire-retardant plastics is that fire-resistant plastics are designed to not catch fire easily until the temperature is exceptionally high. On the other hand, fire-retardant plastics can catch fire even at lower temperatures. However, they burn slowly and extinguish on their own when the fire source is removed.

The performance of these flame retardant materials comes through their special chemical treatment. These chemicals work in various ways, such as absorbing heat, releasing non-flammable gasses, or creating a char layer that helps to stop the spread of fire.

Because of exceptional high heat tolerance (which varies according to the type of plastic), fire-resistant plastics are used in most challenging environments, such as airplanes and even spacecraft. Therefore, fire-resistant plastics are also more expensive than fire-retardant plastics.

Fire-retardant plastics are used in daily life equipment. These include the manufacturing of automotive parts, wirings, everyday appliance casings, and tool handles. Their slow burning rate gives people more time to escape a fire.

Hence, fire-resistant plastics are hard to ignite, while fire-retardant plastics are designed to slow down the fire progression.

| Fonctionnalité | Plastique résistant au feu | Plastique ignifuge |

|---|---|---|

| Behavior in Fire | Does not burn or melt at high temperatures | Slows burning, may self-extinguish when flame source removed, can still melt or drip |

| Niveau de protection | Highest - offers maximum fire safety | Moderate - improves fire safety but not completely fireproof |

| Exemples | Certain types of thermoset plastics, some inorganic polymers | Many thermoplastics with added flame retardant additives |

| Ease of Extrusion | Generally more difficult to extrude due to higher melting points and complex compositions | Generally easier to extrude compared to fire resistant plastics |

Envoyez votre demande maintenant!

La qualité rencontre l'abordabilité. Renseignez-vous maintenant pour des produits de haute qualité à faibles volumes.

Limitations of Flame Retardants

Indeed, fire-resistant plastics offer significant fire safety benefits, yet they do have limitations.

- Firstly, they’re not fireproof, although they resist ignition at extremely high temperatures—They’ll eventually cause them to burn.

- Secondly, some additive flame retardants in these plastics can release toxic fumes when burned. Thus, they pose health risks.

- Additionally, the additives in flame-resistant materials can sometimes affect the mechanical properties of the plastic. So, the material is prone to brittle or less durable.

- Finally, fire-resistant plastics are more expensive than regular plastics.

In short, fire-resistant plastics offer great value for fire safety, but their limitations, like potential burning, toxic fumes, and cost increases, should also be considered.

When Should You Use Flame Retardant Material for Your Project?

Plastics have excellent design flexibility–you can mold them or extrude them. Yet, their flammability can be a concern. Any mishap with your product can compromise the consumers’ trust in you, as it may cost their safety. Thankfully, you can deliver ultimate value to your customers using fire-resistant plastics. Considering these points can help you make more informed decisions according to your project needs.

- What plastic parts of your product will be exposed to heat or potential ignition sources?

- To what extent do you want to add flame retardant performance to your product?

- How much of the risk of burns and smoke inhalation do you want to minimize with your product?

- At the design stage, what fire-resistance level (according to UL94 or other standards) do you want to achieve with your product?

- Notes: UL 94 is a plastics flammability standard that classifies materials with ratings from HB (slow burning) to 5VA (most flame-retardant)

It’s best to seek help from professionals to choose the most suitable fire-resistant plastic parts for your project. They can help you decide on high-quality fire-resistant plastics.

Envoyez votre demande maintenant!

La qualité rencontre l'abordabilité. Renseignez-vous maintenant pour des produits de haute qualité à faibles volumes.

Conclusion

Fire-resistant plastics, with their reduced flammability, offer superb control over flames’ expansion to allow people to save their lives and firefighters time to fight the fire. Although not fireproof, their effectiveness is increasing their demand every day.

Besides this, researchers are also working hard to improve the utility of self-extinguishing plastic to meet the demands of innovative industrial producers. You can choose the right type of fire-safe plastic by assessing your manufacturing goals.

Opt for the Best Fire Resistant Silicone Products by Hongju!

Want to pick the best fire-resistant plastic for your project? Contact Silicone Hongju to get exceptionally fire-safe silicone products ici. Our experts will help you find the perfect silicone o-ring, keypads, gaskets, or seals for your project. Get a free quote and experience